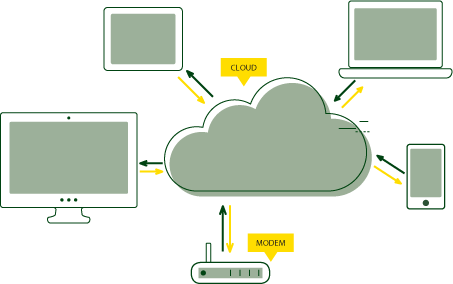

The pumping groups are divided into:

- twin groups

- multi-pump groups

By twin group we mean a pumping group made up of a single pump body on which two motors are mounted.

By multi-pump group we mean a group made up of several identical pump, motor and variable frequency drive elements. Each element shares both the suction and the delivery. Each pump, before flowing into the delivery manifold, must have a non-return valve.

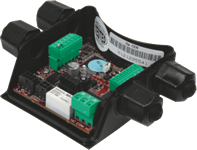

Twin Group Connections

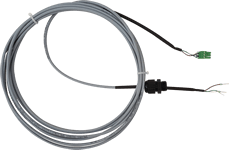

In twin groups the pressure sensor must be connected to the left variable frequency drive (looking at the group from the motor fan side so that the fluid flow goes from bottom to top). For correct operation of the twin system it is necessary that all the external connections of the input terminal block are connected in parallel between the variable frequency drives respecting the numbering of the individual terminals.

If a banging noise is heard during the switch between turning off one motor and turning on the other, then proceed as follows: 1) access the Multipump Group menu page;

2) select the item “Configuration of multipump group parameters”; 3) follow the procedure up to the "Exchange time" item;

4) increase the “Exchange Time” value until the noise disappears;

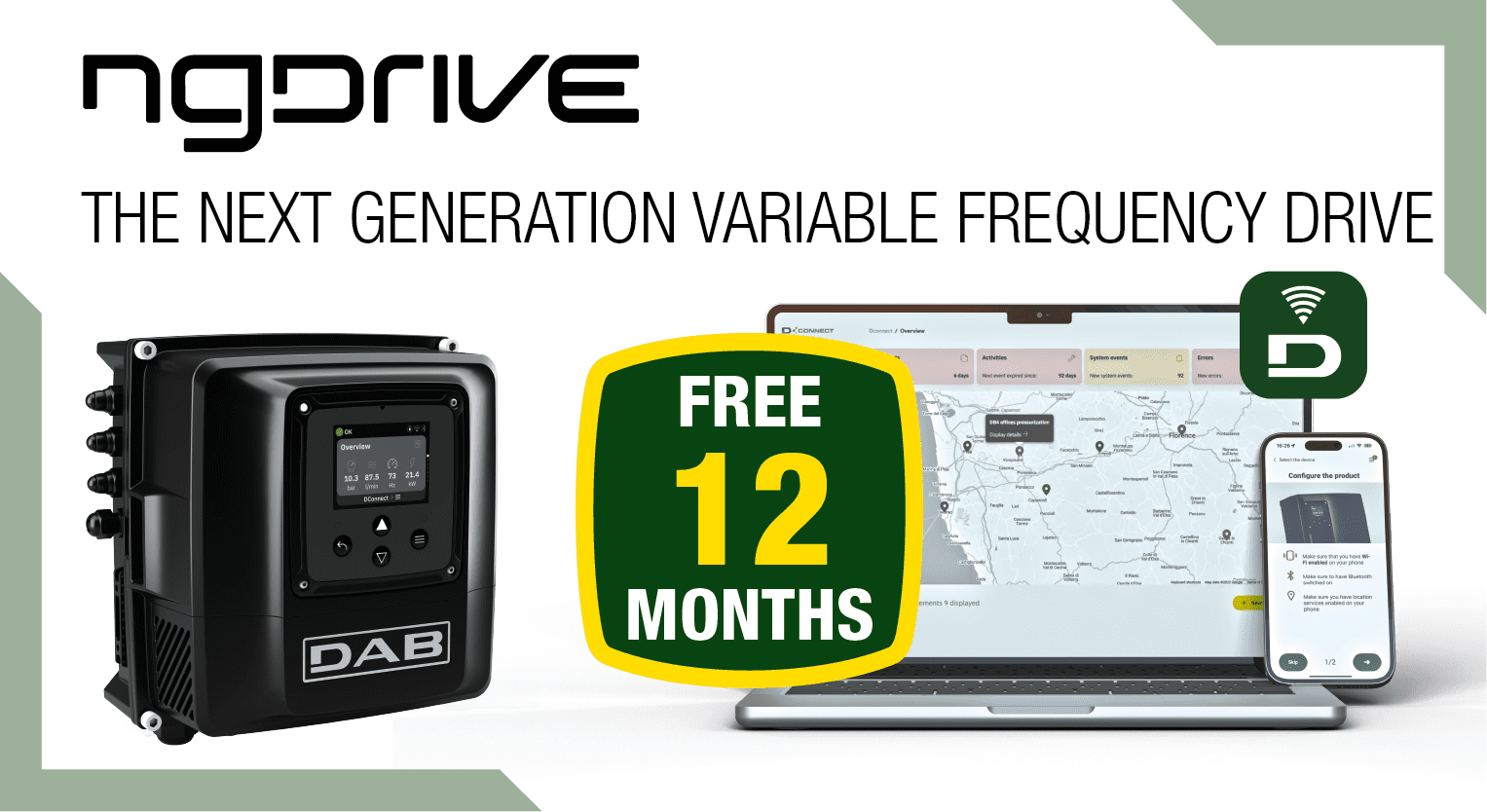

For further information we recommend consulting the

NgDrive instruction manual.

EVOPLUS

EVOPLUS

Aprofundeaza

Aprofundeaza

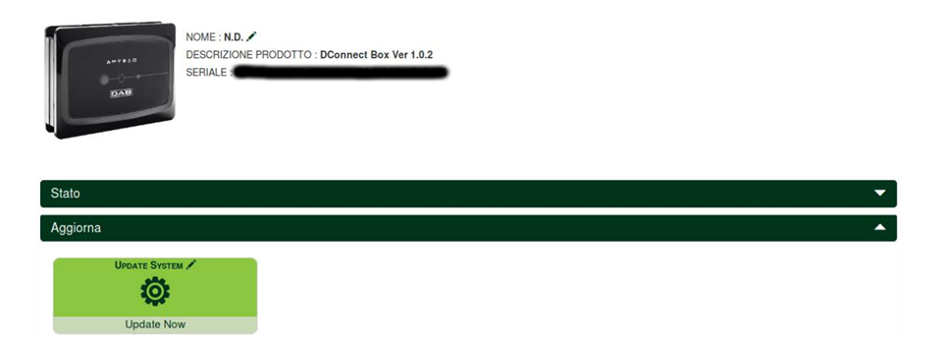

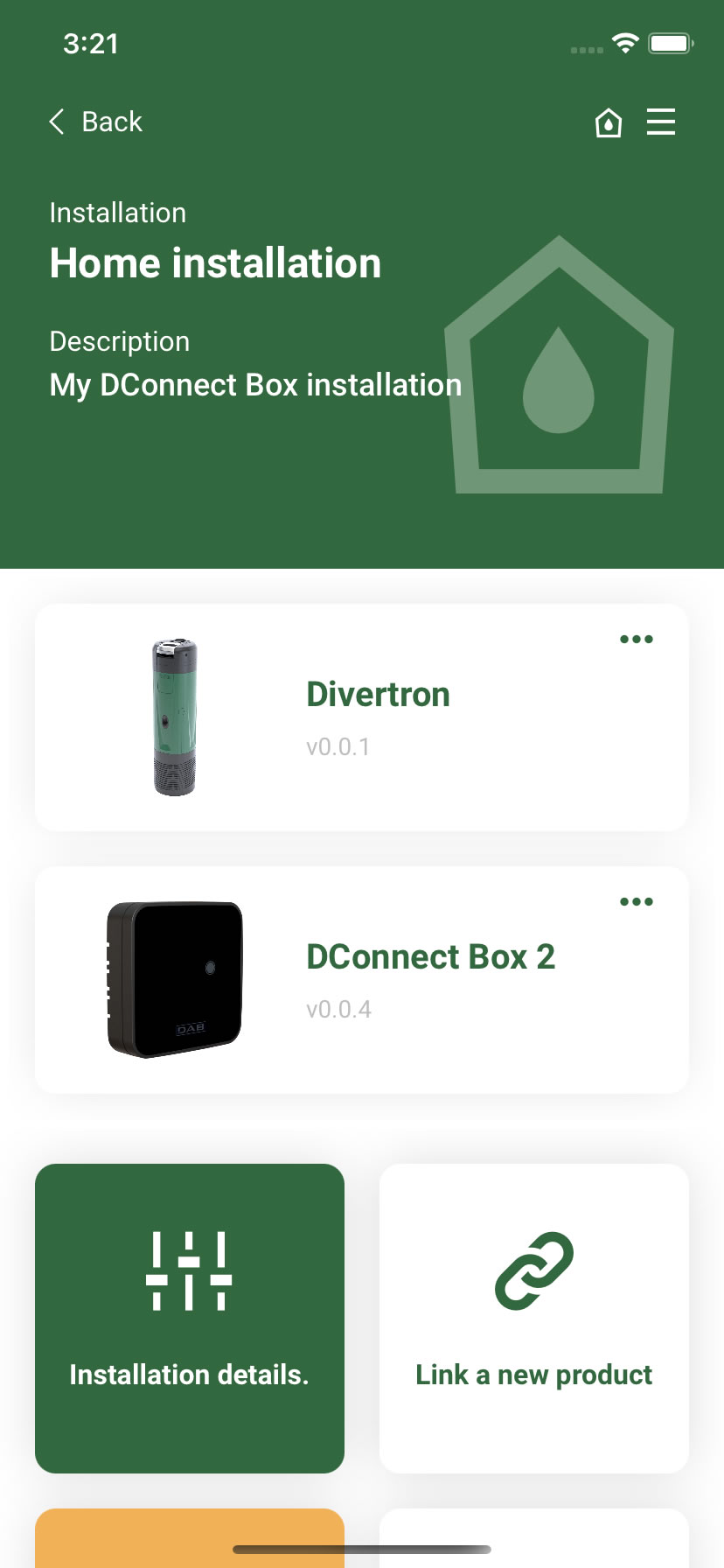

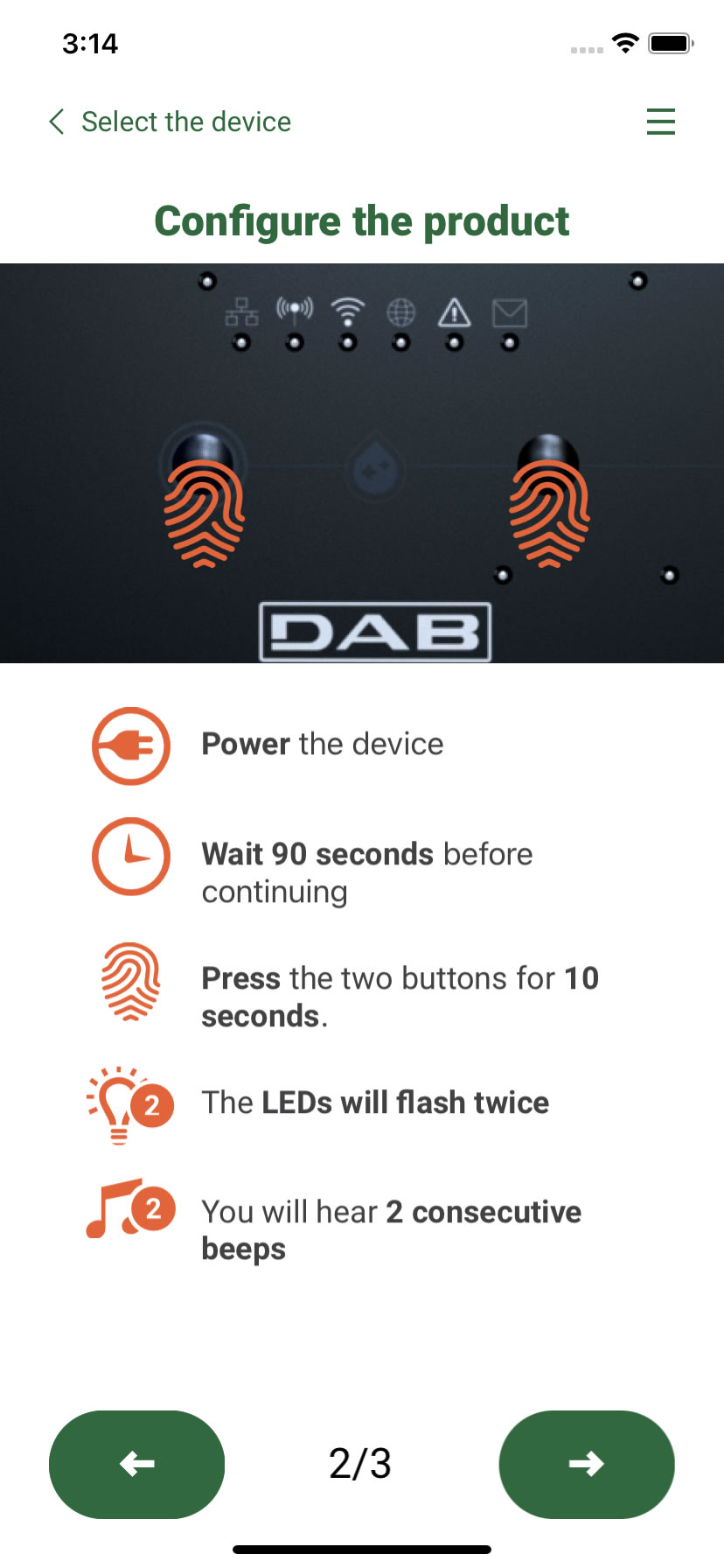

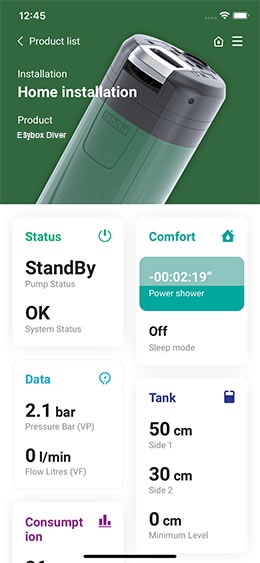

Adaugati la DConnect Box

Adaugati la DConnect Box